Feed size:≤130mm

Motor Power:2x5.5-2x22KW

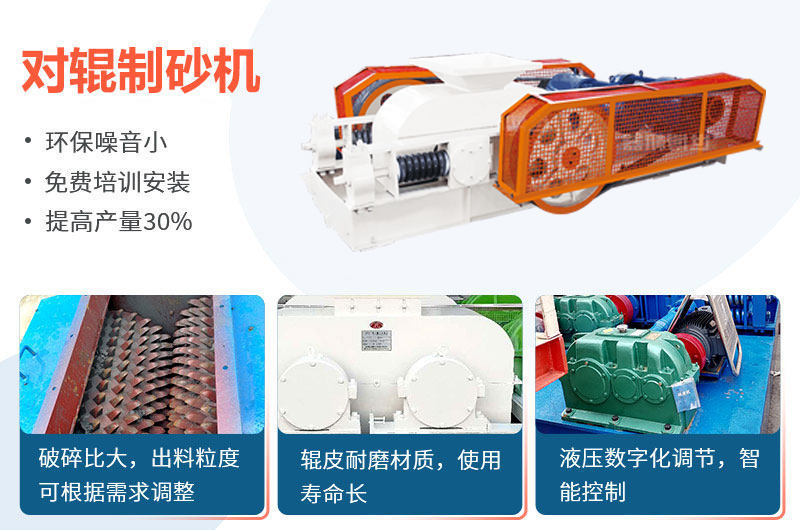

PG double-roll crusher is an environmentally friendly crushing equipment with less dust and low noise. It is mainly composed of rollers, roller support bearings, pressing and adjusting devices, and driving devices. There is a wedge-shaped or gasket adjustment device between the two rollers, which can flexibly adjust the output. The crushed material is cube-shaped and the output particle size is fine. It is widely used in metallurgy, chemical industry, electric power, transportation and other fields. Medium and fine crushing with soft ore.

100% product on-site real shooting, so you can rest assured of your choice!

The input particle size is large, the compressive capacity is strong, and the material with compressive strength ≤ 160MPa can be crushed.

A wedge or gasket adjustment device is installed between the two rollers, the discharge size is easy to control, and the operation of the whole machine is safer.

Compact structure, light weight, small size, for the grinding equipment with the same production capacity requirements, the double roll crusher can save investment.

It is equipped with a dust-proof plate inside and has good sealing performance, which avoids the splashing of fine materials after crushing, and has low noise, which effectively improves the working environment.

When working, the crushed material falls between the two rollers through the feed port for extrusion and crushing, and the finished product is discharged from the discharge port at the lower end. There is a wedge-shaped or gasket adjustment device between the two rollers of the double-roll crusher. There is an adjustment bolt on the top of the wedge-shaped device. When the adjustment bolt block is pulled up, the wedge pushes the movable roller away from the fixed wheel, which means that the two rollers The gap becomes larger, and when the wedge is down, the gap between the two wheels of the movable roller becomes smaller under the action of the compression spring, and the discharge granularity becomes smaller. The shim device adjusts the discharge particle size by increasing or decreasing the quantity or thickness. When the shim is added, the gap between the two rollers becomes larger, and when the shim is reduced, the gap becomes smaller.

| Model | Roll diameter (mm) | Feeding particle size (mm) | Output particle size (mm) | Production (t/h) | Power (kw) |

| 2PG400x250 | φ400 | <25 | ≤3 | 5-10 | 5.5x2 |

| 2PG450x500 | φ450 | <30 | ≤3 | 8-20 | 7.5x2 |

| 2PG610x400 | φ610 | <30 | ≤3 | 13-35 | 15x2 |

| 2PG610x750 | φ610 | <30 | ≤3 | 16-40 | 22x2 |

| 2PG750x500 | φ750 | <30 | ≤3 | 16-40 | 22x2 |

| 2PG800x600 | φ800 | <30 | ≤3 | 20-40 | 30x2 |

| 2PG800x800 | φ800 | <30 | ≤5 | 20-50 | 37x2 |

| 2PGY1000x800 | φ1000 | <30 | ≤5 | 40-70 | 55x2 |

| 2PGY1200x1000 | φ1200 | <30 | ≤5 | 60-100 | 90x2 |

| 2PGY1200x1200 | φ1200 | <30 | ≤5 | 80-130 | 110x2 |

| 2PGY1500x1000 | φ1500 | <30 | ≤5 | 100-150 | 132x2 |

| 2PGY1500x1200 | φ1500 | <30 | ≤5 | 150-200 | 160x2 |

| 2PGY1800x1000 | φ1800 | <30 | ≤5 | 220-300 | 200x2 |

| 2PGY2000x1200 | φ2000 | <30 | ≤5 | 300-400 | 250x2 |

| The above data is for reference only, depending on conditions. | |||||

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services