Feed size:≤45mm

Motor Power:Double motor 110-520KW

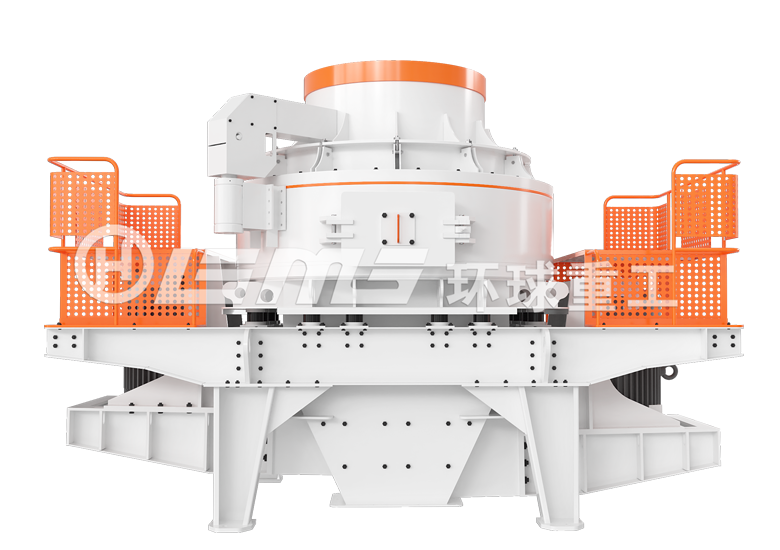

VSI vertical shaft impact sand making machine, also known as fine crusher, is a new generation of impact sand making machine suitable for Chinese customers developed by introducing German sand making technology and combining with my country's working conditions. The equipment has developed a variety of feeding methods and crushing modes. It is a multi-purpose crusher. Compared with similar products, it has high output, good product shape, low cost of use, and 50% energy saving compared with traditional crushers. It has become an important equipment in the fields of stone shaping, artificial sand making, refractory materials and industrial ore product processing.

100% product on-site real shooting, so you can rest assured of your choice!

Large processing capacity, high output, cubic product, good grain shape, reasonable gradation, adjustable fineness modulus, especially suitable for artificial sand making and stone shaping. Compared with traditional equipment with the same power, the output has increased by 30%. .

Each part of the equipment adopts new design and material, which is not only wear-resistant but also more convenient to use with the whole machine. The equipment has a good energy-saving effect, which is 50%-60% energy-saving than traditional sand making machines.

VSI sand making machine is easy to operate and energy-saving. It not only meets the quality requirements of construction sand, but also makes up for the technical defects of the sand making industry. It can be combined and classified according to the different needs of users, and can meet the different process needs of users.

The German original thin oil lubrication station is used, and the double oil pumps complement each other to ensure oil supply, automatic shutdown when there is no oil flow, and no oil pressure; the oil cooling and heating device ensures that the bearing lubrication is always in good condition, thus completely solving the problems of bearing heating and making the spindle bearing Maintain a constant temperature to prolong maintenance intervals and service life.

VSI vertical shaft impact sand making machine uses high-speed moving materials to crush each other by themselves and the friction between materials to crush. There are two feeding methods: full center feeding, sudden falling and center feeding. The material falls into the hopper of the sand making machine, enters the high-speed rotating wheel through the central feeding hole, is rapidly accelerated in the wheel, and its acceleration can reach dozens of times the acceleration of gravity, and then shoots out from the wheel at high speed, firstly with the After rebounding, another part of the material that falls freely hits, and then hits the material lining (rock-on-rock) or counter-attack block (stone-on-iron) together, and is rebounded and impacted obliquely upwards to the top of the vortex chamber, and then changes its direction of motion, deflecting to It moves downward and collides with the material emitted from the impeller channel to form a continuous material curtain. So the materials are hit, rubbed and grinded for two or more times in the eddy current crushing cavity, and the crushed materials will be discharged from the lower discharge port.

| Type | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | |

| Production capacity (t/h) | Cascade and Center Feed | 120-180 | 200-260 | 300-380 | 450-520 |

| Full Center Feed | 60-90 | 100-130 | 150-190 | 225-260 | |

| Inlet size | soft material | ≤35 | ≤40 | ≤45 | ≤50 |

| hard material | ≤30 | ≤35 | ≤40 | ≤45 | |

| speed | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Double motor power (kw) | 110-150 | 180-220 | 264-320 | 400-440 | |

| Dimensions (mm) | 3700x2150x2100 | 4140x2280x2425 | 4560x2447x2778 | 5000X2700X3300 | |

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | |

| Power | 380V:50Hz | ||||

| vibration sensor | Monitoring range: 0.1-20mm/s continuously adjustable | ||||

| Thin oil lubrication station | Double oil pump motor power | 2×0.31kw | |||

| Security Protection | Double oil pumps complement each other to ensure oil supply; no oil flow, no oil hydraulic automatic shutdown; water cooling and cooling; winter motor heating start D | ||||

| Dimensions (mm) | 820×520×1270 | ||||

| Fuel tank heater power (kw) | 2KW | ||||

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services