Feed size:≤369mm

Motor Power:75-315KW

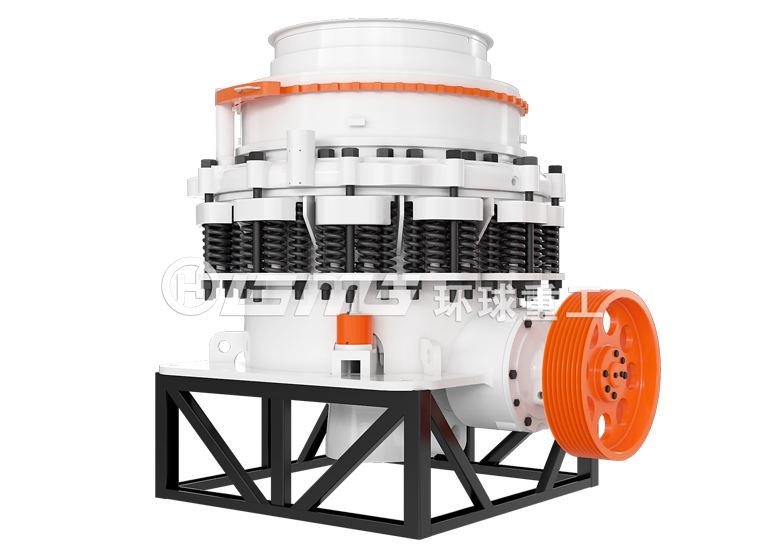

Compound cone crusher is a comprehensive cone crusher with spring and hydraulic cylinder in the cone crusher, and its performance technology has reached the advanced level abroad. The combination of high-performance crushing cavity and high crushing frequency makes the material to be crushed finer, and the crushing capacity is higher than similar models. At the same time, it also enhances the lamination crushing effect between material particles, effectively improving the crushing efficiency of materials. The final three-dimensional shape. The compound cone crusher adopts a hydraulic cavity clearing system, which makes the operation easier to automate and reduces downtime. After optimized design, the trouble-free operation rate exceeds 95%, which effectively improves production efficiency. CS series cone crushers have standard type and short head type, and each model is equipped with multiple cavity types, which can be applied to the medium and fine crushing operations of materials with various hardness. It has been shown in a large number of practical applications, especially in the The performance is more prominent during the medium crushing operation.

100% product on-site real shooting, so you can rest assured of your choice!

The compound cone crusher consists of a standard type and a short head type, each All models have four types of crushing chambers: coarse, medium, fine, and superfine, which can crush materials with medium hardness or above.

Adopted the principle of laminated crushing and multi- The concept design of crushing and less grinding makes it have higher output than the same type of machines, and the particle shape of the crushed material is more uniform.

Through hydraulic insurance, hydraulic locking, hydraulic The use of adjustment, hydraulic cavity cleaning and other devices makes the operation more automatic, and the equipment adopts an optimized design. Under normal use, the trouble-free operation rate exceeds 95%, which greatly improves the production efficiency.

The body of the compound cone crusher is uniform The cast structure is equipped with reinforcement ribs at the high stress points of the heavy-duty parts. The independent thin oil lubrication system and automatic control make the equipment more durable and reliable in operation.

When the compound cone crusher is working, the motor drives the eccentric sleeve to rotate through the V-belt, transmission shaft and bevel gear pair. The crushing cavity is continuously impacted, squeezed and bent, and then crushed, and the crushed ore is discharged from the discharge port.

| Model | Diameter of moving cone (mm) | cavity | Feed opening size (mm) | Outlet size (mm) | Spindle speed (r/min) | Motor power (kw) | Output (t/h) | Dimensions (mm) | |

| Feed size (mm) | Open side opening size (mm) | ||||||||

| CS75 | 910 | thin thick |

83 159 |

102 175 |

9-22 13-38 |

580 | 75 | 45-91 59-163 |

2821 × 1880 × 2164 |

| CS110 | 1200 | Thin | 127 | 131 | 9-31 | 485 | 110 | 63-188 | 2821 × 1974 × 2651 |

| Medium | 156 | 156 | 13-38 | 100-200 | |||||

| Bold | 178 | 191 | 19-51 | 141-308 | |||||

| CS160 | 1295 | Thin | 109 | 137 | 13-31 | 485 | 160 | 109-181 | 2800 × 2342 × 2668 |

| Medium | 188 | 210 | 16-38 | 132-253 | |||||

| Bold | 216 | 241 | 19-51 | 172-349 | |||||

| CS220 | 1395 | Thin | 155 | 173 | 25-65 | 485 | 220 | 180-285 | 3360 × 2650 × 3050 |

| Medium | 188 | 198 | 22-50 | 215-330 | |||||

| Bold | 230 | 245 | 19-45 | 230-570 | |||||

| CS250 | 1650 | Thin | 188 | 209 | 16-38 | 485 | 250 | 181-327 | 3911 × 2870 × 3771 |

| Medium | 213 | 241 | 22-51 | 528-417 | |||||

| Bold | 241 | 268 | 25-64 | 299-635 | |||||

| CS315 | 2134 | Thin | 253 | 278 | 19-38 | 435 | 315 | 281-726 | 4631 × 3251 × 4732 |

| Medium | 303 | 334 | 25-51 | 608-998 | |||||

| Bold | 334 | 369 | 31-64 | 789-1270 | |||||

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services