Feed size:≤1360mm

Motor Power:75-450KW

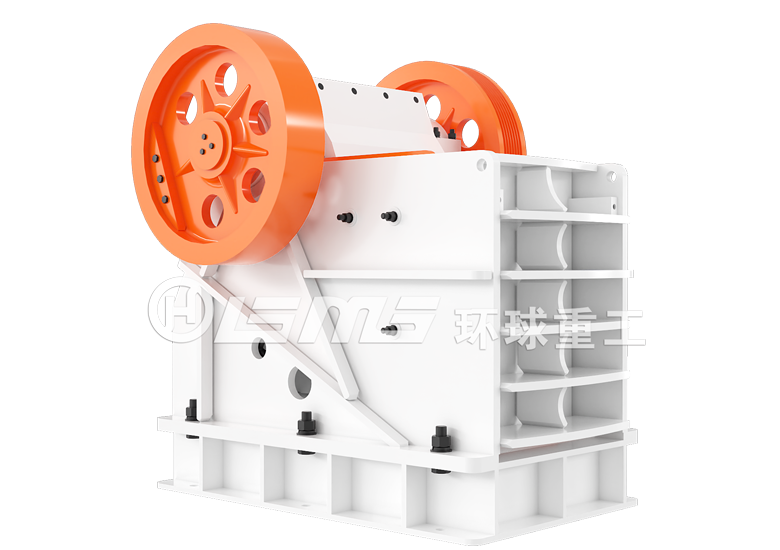

Compared with the traditional jaw crusher, the SD German version of the jaw crusher has been greatly improved in terms of motion parameters, machine structure, and adjustment methods. The integrated structure design of the motor base and the main machine makes the machine occupy less space and run more smoothly, and has more advantages in transportation, installation, maintenance and adjustment, and is especially suitable for fixed production lines and mobile crushing. The crushing chamber adopts a symmetrical "V" design, with a large inclination angle of the toggle plate, a large stroke, and a reasonable speed, so that the feed particle size is larger, the output is higher, the particle size is more uniform, the wear of the jaw plate is reduced, and the maintenance rate and failure rate of the machine are reduced. The service life is extended and the overall cost is lower.

100% product on-site real shooting, so you can rest assured of your choice!

Adopting the integrated structure design of the motor base and the main engine, the machine occupies a small space, runs more smoothly, and is convenient for transportation, installation, maintenance and adjustment.

The bearing seat adopts integral cast steel structure, the bearing specification is increased, the bearing capacity is stronger, and the service life is prolonged.

The discharge port adopts a wedge-type adjustment device, which has a wide range of discharge adjustment, increases the flexibility of the equipment, and can meet the needs of different users.

The movable jaw assembly is made of high-quality steel castings, and the heavy-duty eccentric shaft is processed by segment billet, which makes the equipment have extraordinary reliability and durability.

The main structure of the German version of the jaw crusher is composed of frame, eccentric shaft, fixed jaw, movable jaw, toggle plate, spring rod and other components. Its working principle is that the motor drives the belt and the pulley, and the movable jaw moves up and down according to the predetermined track through the eccentric shaft. When the movable jaw plate pushes to the fixed fixed jaw plate, the material is crushed or chopped by gravity. When the plate retreats, the crushed materials are discharged from the lower opening of the crushing chamber. With the continuous rotation of the eccentric shaft, the movable jaw of the crusher performs periodic crushing motions, and the materials entering the crushing chamber are continuously crushed and discharged, realizing continuous production.

| Model | Inlet size (mm) | Maximum feed size (mm) | Discharge opening size (mm)/processing capacity (t/h) | Power (kw) | |||||||||||

| 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 250 | ||||

| JC100 | 1000×630 | 600 | 90-160 | 120-180 | 130-190 | 150-200 | 160-210 | 180-230 | 75 | ||||||

| JC110 | 1100×850 | 720 | 180-240 | 200-265 | 220-295 | 245-320 | 300-385 | 350-455 | 400-520 | 460-590 | 110 | ||||

| JC125 | 1250×950 | 810 | 270-360 | 325-430 | 385-505 | 445-580 | 500-650 | 560-725 | 620-800 | 160 | |||||

| JC140 | 1400×1070 | 910 | 360-470 | 425-555 | 490-640 | 555-725 | 625-815 | 690-900 | 725-985 | 200 | |||||

| JC160 | 1600×1200 | 1020 | 490-640 | 560-730 | 635-825 | 710-920 | 780-1010 | 855-1105 | 930-1200 | 250 | |||||

| JC210 | 2100×1600 | 1360 | 800-880 | 900-1005 | 1000-1125 | 1100-1225 | 1200-1375 | 1300-1500 | 450 | ||||||

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services