Feed size:≤268mm

Motor Power:75-250KW

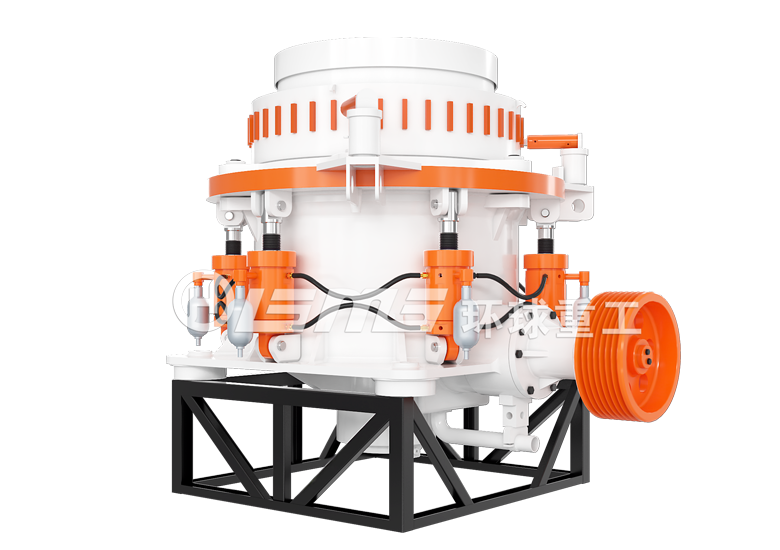

The full hydraulic cone crusher is a new generation of high-performance crushing equipment developed and produced by Henan Global Heavy Industry, which introduces foreign advanced design concepts and integrates the advantages of other cone crushers. Its internal structure is novel and unique, easy to maintain, low in manufacturing cost, high in production capacity, excellent in hydraulic adjustment and overload protection, especially in automatic control, and has become one of the equipment with high utilization rate in crushing operations. It is widely used in metallurgy, building materials, mining, refractory materials, cement, abrasives and other industries for material crushing. It is especially suitable for crushing and crushing hard materials such as various mines and rocks, such as granite, limestone, sandstone and pebbles.

100% product on-site real shooting, so you can rest assured of your choice!

The equipment adopts hydraulic adjustment of the discharge port, hydraulic protection and hydraulic cavity cleaning device, which has a high degree of automation, reduces downtime, saves the user's manpower and material resources, and its reliability and life are greatly improved.

Through the special crushing cavity designed by the principle of intergranular lamination and the matching speed, the selective crushing of materials is realized, and the proportion of fine materials and cube content of the product is effectively improved.

The structure of the equipment is simple and easy to operate. All parts can be disassembled and repaired from the top or side, which makes the maintenance and inspection of the equipment very convenient and saves time and effort.

The unique thin oil lubrication system design and high-performance non-contact labyrinth seals are wear-free, which improves the reliability of blocking dust and greatly improves the service life of the equipment.

The full hydraulic cone crusher is composed of upper frame and fixed cone, adjusting ring, lower frame, fixed central shaft, moving cone and spherical shoe, eccentric sleeve and sector gear, pinion and horizontal shaft, peripheral hydraulic cylinder, Hydraulic station, lubrication station and other components. When working, the rotation of the motor drives the pulley or coupling, the transmission shaft and the cone to make the eccentric shaft do periodic swinging motion under the axis line. After the material enters the crushing cavity from the feed port, it is squeezed, ground and kneaded by the mutual impact of the eccentric shaft and the wall of the rolling socket to produce crushing effect. The hydraulic insurance system can remove the faulty objects from the top of the support sleeve and the fixed cone through hydraulic pressure when the machine has an iron fault or a stuffy car phenomenon. While playing a good insurance role, it greatly reduces the maintenance rate and improves production. efficiency.

| Model | Diameter of moving cone (mm) | cavity | Feed opening size (mm) | Outlet size (mm) | Spindle speed (r/min) | Motor power (kw) | Output (t/h) | Dimensions (mm) | |

| Feed size (mm) | Open side opening size (mm) | ||||||||

| SHQ300 | 910 | thin thick |

83 159 |

102 175 |

9-22 13-38 |

580 | 75 | 48-96 65-168 |

2821 × 1880 × 2164 |

| SHQ400 | 1200 | Thin | 127 | 131 | 9-31 | 485 | 110-160 | 68-192 | 2821 × 1974 × 2651 |

| Medium | 156 | 156 | 13-38 | 105-205 | |||||

| Bold | 178 | 191 | 19-51 | 146-308 | |||||

| SHQ500 | 1395 | Thin | 155 | 173 | 25-65 | 485 | 220-250 | 180-290 | 3360 × 2650 × 3050 |

| Medium | 188 | 198 | 22-50 | 220-335 | |||||

| Bold | 230 | 245 | 19-45 | 235-575 | |||||

| SHQ600 | 1650 | Thin | 188 | 209 | 16-38 | 485 | 250-280 | 186-332 | 3911 × 2870 × 3771 |

| Medium | 213 | 241 | 22-51 | 263-422 | |||||

| Bold | 241 | 268 | 25-64 | 304-640 | |||||

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services