Feed size:Depends on model

Adjustment range of outlet:≤45mm

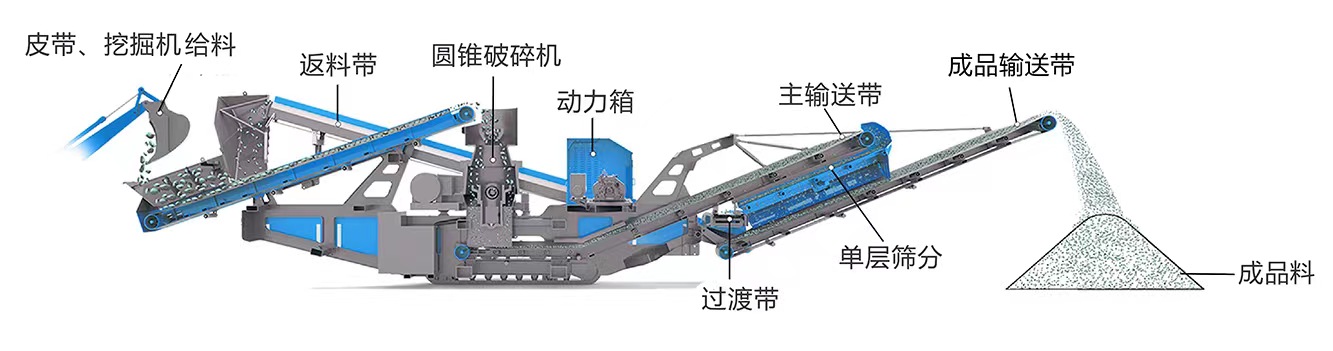

河南环球重工履带式中碎和细碎移动破碎站(圆锥履带移动破碎站)是一种种率的破碎设备,主要用于:河道治理、鹅卵石破碎以及城市的拆迁现场、建筑垃圾处理以及其他各种需要经常移动搬迁的场地作业中的二级、三级破碎。采用履带式的驱动方式,技术过硬,功能齐全,在复杂地形条件下,此设备均可直接开到工作场地的任意位置,不需运输。成品粒度可根据客户需求灵活调节,成本少,收益好。履带式移动破碎站可量身定制满足不同规模的生产破碎作业,物料适用范围广。

100% product on-site real shooting, so you can rest assured of your choice!

The chassis adopts a crawler-type fully rigid ship-type structure, which has high strength, low grounding ratio, and good passability. It can adapt to mountains, wetlands and other landforms, and has good adaptability.

履带式移动破碎站产品具有重量轻、体积小,整机采用全轮驱动,可实现原 地转向,特别适合狭窄场地工作。

满足矿山,水电站,煤矿等工程破碎要求。

可量身定制不同规模的生产破碎作业,满足客户个性化需求;成品粒度可根据客户需求灵活调节,成本少,收益好

Global Heavy Industries crawler mobile crushing station consists of crawler chassis, frame assembly, main engine and auxiliary equipment, power system and hydraulic electric control system. When moving, the power system is used to provide power, and the hydraulic electric control system drives the crawler chassis to walk; when installing, the power system controls and drives hydraulic cylinders through the hydraulic electric control system to automatically complete the equipment installation; The control system drives and controls the work of the main engine and auxiliary equipment. After the material enters the main engine mounted on the crawler chassis and frame from the silo, it is crushed or screened, and then discharged through the integrated belt conveyor.

| Model | TF150 | TF250 Counterattack Breaker | TF250 counterattack standard car |

| Feeder | |||

| Device | GZD1038 | ZDG1228 | ZDG1228 |

| Vibration motor | 2x3.7KW | 5.5KW*2 | 5.5KW*2 |

| Motor drive | Motor drive | Motor drive | |

| Crushers | |||

| Device | LF150 | LF250 | LF250 |

| Maximum Feed Size | 400mm | 500mm | 500mm |

| Motor and drive mode | 160KW | 250KW | 250KW |

| Motor drive | Motor drive | Motor drive | |

| Frame | |||

| Hydraulic track chassis | NS415E | NS415E | NS415E |

| Boat frame | Q345B welding | Q345B welding | Q345B welding |

| Main Belt Conveyor | |||

| Specifications | B800*11 meters | B1200*11 meters | B1200*11 meters |

| Motor reducer | 11KW | Motor reducer drive 15KW | Motor reducer drive 15KW |

| Loop polyester canvas strap | EP300-B1200*5(6.0+1.5) | EP300-B1200*5(6.0+1.5) | |

| Transfer belt conveyor | |||

| Specifications | B500*2 meters | B500*2.4m | B500*2.4m |

| Motor reducer | 4KW | Motor reducer drive 4KW | Motor reducer drive 4KW |

| Loop polyester canvas strap | EP200-B500*3(4.5+1.5) | EP200-B500*3(4.5+1.5) | |

| Under screen belt conveyor | |||

| Specifications | B1000*5 meters | B1200*6.2m | B1200*6.2m |

| Motor reducer | 5.5KW | Motor reducer drive 7.5KW | Motor reducer drive 7.5KW |

| Loop polyester canvas strap | EP300-B1200*5(4.5+1.5) | EP300-B1200*5(4.5+1.5) | |

| Return belt conveyor | |||

| Specifications | B500*7.7m | B500*9.3m | B500*9.3m |

| Driver method | 5.5KW | Motor reducer drive 4KW | Motor reducer drive 4KW |

| Loop polyester canvas strap | EP200-B500*3(4.5+1.5) | EP200-B500*3(4.5+1.5) | |

| Return screen | |||

| Specifications | 2YK1530 | YS1320 | GLS1630FA |

| Motor | 11KW | 3.7KW*2 | 3KW*2 |

| Driver method | Motor | Motor drive | ROST spring |

| Iron remover | |||

| Specifications | RCYQ-13 | RCYQ-13 | RCYQ-13 |

| Motor reducer | 3KW | Motor reducer drive 3KW | Motor reducer drive 3KW |

| Powertrain | |||

| generator set | 320KW Cummins generator set | 500KW generator set | 500KW generator set |

| Electrical system | Adopt PLC intelligent control system, with fault alarm and fault record query function, visualized workflow, easy operation, screen display of various parameter monitoring, engine speed can be automatically adjusted according to load conditions. | The main motor of the impact crusher is started by frequency conversion, other motors are started directly, and the main electrical components are Schneider | The main motor of the impact crusher is started by frequency conversion, other motors are started directly, and the main electrical components are Schneider |

| Hydraulic system | Belt Conveyor Folding Oil Cylinder and Impact Crusher Oil Cylinder Hydraulic Pump, Valve, Station and Oil Pipe Accessories | Unpacking and adjustment of the discharge gap, side discharge folding and disassembly of the return part, load sensitive type, electro-hydraulic proportional valve walking valve group | Unpacking and adjustment of the discharge gap, side discharge folding and disassembly of the return part, load sensitive type, electro-hydraulic proportional valve walking valve group |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services