Feed size:depending on the process

Adjustment range of outlet:depending on the process

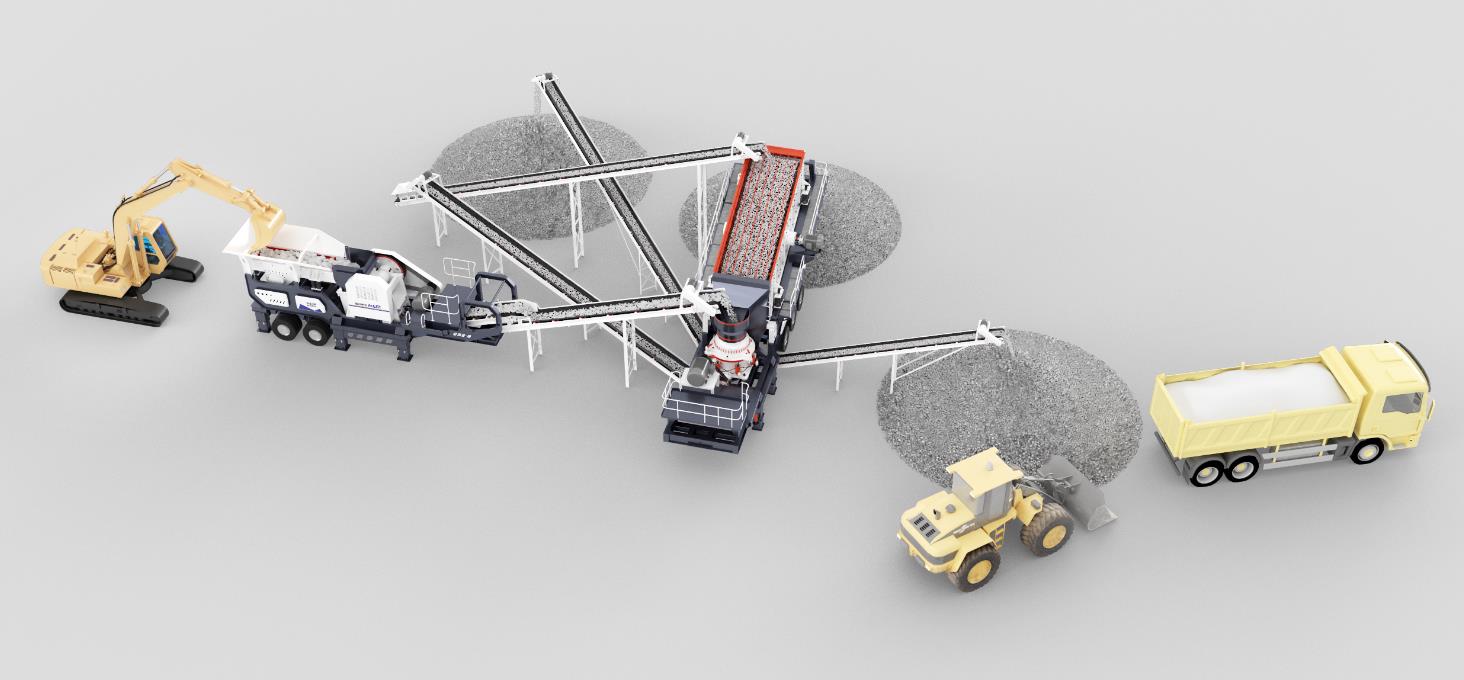

In the application of mobile crushing station, it is used in two-stage and three-stage medium and fine crushing. Equipped with high-performance and high-capacity impact crushers or CS, S single-cylinder, and HP series cone crushers, it can achieve high productivity, large crushing ratio and better grain shape. The combination design of crushing stroke, crushing speed and crushing chamber shape has been proved by experiments that this combination design is superior to the old-fashioned cone crusher in terms of performance, efficiency, production capacity and finished product quality.

100% product on-site real shooting, so you can rest assured of your choice!

Newly equipped with large capacity single cylinder cone crusher.

Large crushing ratio, high productivity and better finished grain shape.

Integrated installation, with its own conveyor, reducing equipment configuration and investment costs.

The installation angle of the vibrating screen can be adjusted to make the processing capacity of the whole machine more powerful

The medium and fine crushing, shaping and screening mobile station relies on external electric power to drive the main engine and auxiliary motor to drive the work. The material is evenly conveyed to the cone crusher by the feeder for preliminary crushing, and then passes through the circular vibrating screen to form a closed circuit system to realize the circular crushing of the material, and the finished material is output by the conveyor. The tire cone crusher + vibrating screen mobile crushing station can remove the circular vibrating screen according to actual production needs, and realize the direct primary crushing of crushed materials. It is convenient and flexible to use with other crushing equipment.

| Standard models | Feed size (mm) | Processing capacity (t/h) | ||

| S-CS75 | ≤160 | 59-163 | ≤160 | 59-163 |

| S-CS110 | ≤178 | 100-200 | ≤178 | 100-200 |

| S-CS160 | ≤188 | 132-253 | ≤188 | 132-253 |

| S-CS220 | ≤230 | 215-330 | ≤230 | 215-330 |

| S-Q300 | ≤160 | 105-205 | ≤160 | 105-205 |

| S-Q400 | ≤230 | 235-575 | ≤230 | 235-575 |

| S-Q500 | ≤240 | 304-640 | ≤240 | 304-640 |

| S-H420 | ≤240 | 85-170 | ≤240 | 85-170 |

| S-H430 | ≤360 | 120-345 | ≤360 | 120-345 |

| S-H440 | ≤450 | 255-605 | ≤450 | 255-605 |

| S-HP100 | ≤140 | 75-140 | ≤140 | 75-140 |

| S-HP200 | ≤185 | 145-250 | ≤185 | 145-250 |

| S-HP300 | ≤230 | 220-440 | ≤230 | 220-440 |

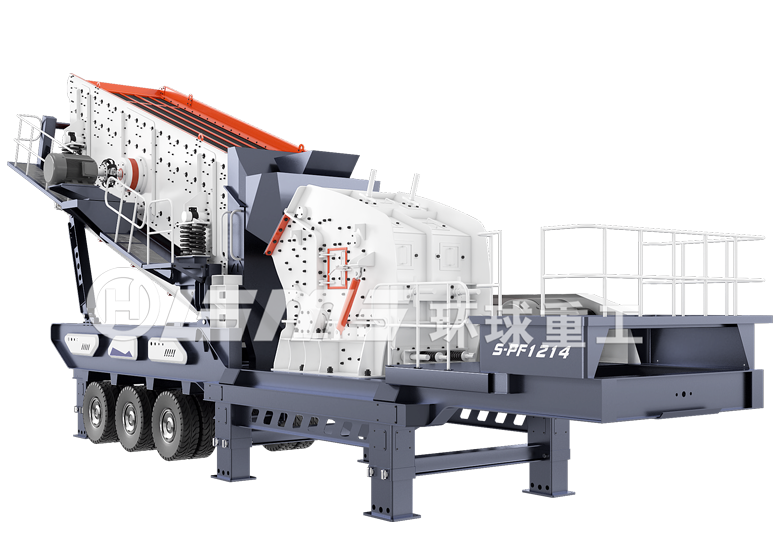

| S-PF1214 | ≤300 | 100-200 | ≤300 | 100-200 |

| S-PF1315 | ≤350 | 130-280 | ≤350 | 130-280 |

| S-PF1320 | ≤500 | 180-400 | ≤500 | 180-400 |

| S-S1860 | ≤400 | 65-586 | ≤400 | 65-586 |

| S-S2160 | ≤400 | 81-720 | ≤400 | 81-720 |

| S-S2460 | ≤400 | 100-810 | ≤400 | 100-810 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services