Spiral diameter:300-3000mm

Motor Power:1.1-40KW

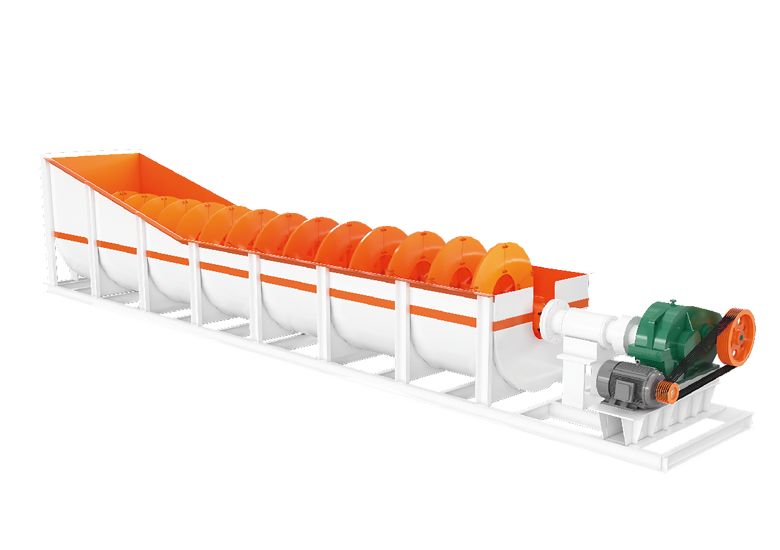

Spiral classifiers mainly include high-weir single-screw and double-screw, low-weir single-screw and double-screw, and submerged single-screw and double-screw classifiers. The principle of different sedimentation speeds is a kind of equipment for mechanical classification. Spiral classifiers are widely used in beneficiation plants to form a closed-circuit cycle with ball mills to separate ore sands, or to classify ore sand and fine mud in gravity beneficiation plants, and to classify ore pulp in metal beneficiation processes, and to wash ore Desliming, dehydration and other operations in the operation are one of the main equipment for beneficiation.

100% product on-site real shooting, so you can rest assured of your choice!

The equipment adopts frequency conversion control, which has a high degree of automation and simple and convenient operation; in the closed-circuit grinding circuit, it can be connected with the mill by gravity, and compared with the hydrocyclone, the power consumption is lower.

It is widely used in the classification of ore sand and fine mud in the gravity concentrator, and in the particle size classification of the ore pulp in the metal beneficiation process, as well as the desliming and dehydration in the ore washing operation.

The classification fineness of the classifier is high, and the oversized particles and sieve residues in the product are eliminated; the quality of the stone powder is easy to control, and the fineness adjustment is convenient and flexible.

The lower support of the machine adopts a live shaft sleeve and nylon bearing shell structure, which is easy to maintain and replace; the base is made of channel steel, and the body is welded with steel plates; the water inlet and shaft head of the screw shaft are made of pig iron sleeves, which are wear-resistant and durable.

The spiral classifier is based on the principle that the solid particles have different sizes and specific gravity, so the sedimentation speed in the liquid is different. The fine ore particles float in the water and overflow, and the coarse ore particles sink to the bottom of the tank. It is a kind of grading equipment that is pushed to the upper part by the screw to carry out mechanical grading. It can classify the powder ground in the mill to filter, and then use the spiral blade to screw the coarse material into the feed port of the mill, and filter it. The fine material discharged from the overflow pipe. The base of the machine is made of channel steel, and the body is welded with steel plates. The water inlet head and shaft head of the screw shaft are made of pig iron sleeves, which are wear-resistant and durable. The lifting device is divided into two types: electric and manual.

| Specification model | Helix diameter (mm) | Sink length (mm) | Screw speed (r/min) | Processing capacity (t/h) | Motor power (kw) | Dimensions (L×W×H)(mm) | Total weight (t) | ||||

| Click to return sand | Press overflow | For transmission | For lifting | long | wide | high | |||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | ---- | 3850 | 490 | 1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | ---- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | ---- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | ---- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | ---- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73 |

| 2FC-30 | 14300 | 23300 | 1410 | ---- | ---- | 17091 | ---- | 8680 | 84.8 | ||

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services