Feed size:≤25mm

Motor Power:18.5-4500KW

Ball mill is one of the high-fine grinding machines widely used in industrial production, and it is the key equipment for crushing materials after they are crushed. Ball mills are suitable for grinding various ores and other materials, and are widely used in black and non-ferrous metal beneficiation, cement, building materials, chemicals, refractory materials, and glass ceramics industries. They can be divided into dry and wet grinding methods. According to different discharge methods, it can be divided into grid type and overflow type. According to the shape of the cylinder, it can be divided into four types: short cylinder ball mill, long cylinder ball mill, tube mill and conical mill. Users can make different types according to different needs. choose.

100% product on-site real shooting, so you can rest assured of your choice!

The machine adopts the integrated structure of the machine body and the bottom frame. It can be hoisted on the foundation plane at one time during installation, and the operation and maintenance work is simpler. The equipment has no inertial impact, and the operation is stable, which reduces the downtime and maintenance time of the mill and improves the efficiency. .

The main bearing adopts a large-diameter double-row self-aligning roller bearing instead of the original sliding bearing, which can reduce friction and energy consumption by 30%, improve fine grain size, and increase processing energy by 15%-20%.

The wearing parts are casted with good wear-resistant steel, the hollow shaft is made of cast steel, and the inner lining can be replaced; , the equipment has a longer service life.

Install smoke and dust filtration system, dust removal and noise reduction equipment to control dust and noise pollution within the standard range, and at the same time use grease spindle lubrication to avoid heavy metal pollution and fully realize green production standards.

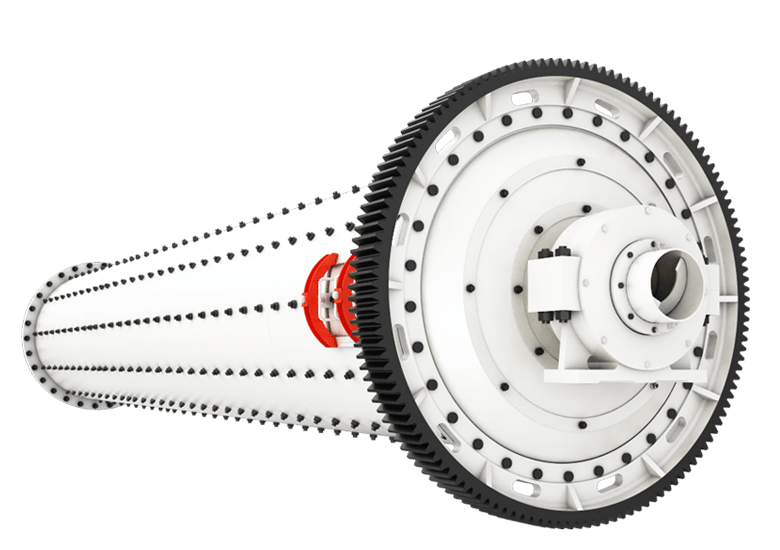

The ball mill is a horizontal cylindrical rotating device, driven by outer gears, two warehouses, and a lattice type ball mill. It is composed of feeding part, discharging part, rotary part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts. The material enters the first chamber of the mill evenly and spirally through the feeding hollow shaft from the feeding device. There are stepped lining boards or corrugated lining boards in the chamber, and steel balls of various specifications are installed inside. The rotation of the cylinder produces centrifugal force to bring the steel balls to a certain level. After falling from a high height, it will impact and grind the material. Materials get coarse grind in the first warehouse, then into the second warehouse through the single-compartment. The second warehouse has flat liner and also filled with balls , then grind the material again. The powder is discharged through the unloading grate plate to complete the grinding operation.

| Specification model | Cylinder speed (r/min) | Loading ball (t) | Feed size (mm) | Output particle size (mm) | Production (t/h) | Motor power (kw) | Total weight (t) |

| Φ900 x 1800 | 36 | 1.5 | ≤20 | 0.075-0.89 | 0.65 - 2 | 18.5 | 5.5 |

| Φ900 x 3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1- 3.5 | 22 | 6.7 |

| Φ1200 x 2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5- 4.8 | 30 | 12 |

| Φ1200 x 3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200 x 4500 | 36 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Φ1500 x 3000 | 32.4 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500 x 4500 | 29.7 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500 x 5700 | 27 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830 x 3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 29 |

| Φ1830 x 4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830 x 6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Φ1830 x 7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100 x 3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5- 36 | 155或180 | 34.8 |

| Φ2100 x 4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8- 43 | 245 | 42 |

| Φ2100 x 7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8- 48 | 280 | 56.6 |

| Φ2200 x 4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9- 45 | 280 | 51.8 |

| Φ2200 x 6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200 x 7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200 x 7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400 x 3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400 x 4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700 x 4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 12-80 | 40 0 | 94 |

| Φ2700 x 4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200 x 4500 | 18 | 65 | ≤25 | 0.074-0.4 | According to process conditions | 630 | 137 |

| Φ3600 x 4500 | 17 | 90 | ≤25 | 0.074-0.4 | According to process conditions | 10 00 | 158 |

| Φ3600 x 6000 | 17 | 110 | ≤25 | 0.074-0.4 | According to process conditions | 1250 | 175 |

| Φ3600 x 8500 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8 - 256 | 1800 | 252 |

| Φ4000 x 5000 | 16.9 | 121 | ≤25 | 0.074-0.4 | 45 - 208 | 1500 | 203 |

| Φ4000 x 6000 | 16.9 | 146 | ≤25 | 0.074-0.4 | 65 - 248 | 1600 | 218 |

| Φ4000 x 6700 | 16.9 | 149 | ≤25 | 0.074-0.4 | 45 - 252 | 1800 | 238 |

| Φ4500 x 6400 | 15.6 | 172 | ≤25 | 0.074-0.4 | 54 - 306 | 2000 | 280 |

| Φ5030 x 6400 | 14.4 | 216 | ≤25 | 0.074-0.4 | 68 - 386 | 2600 | 320 |

| Φ5030 x 8300 | 14.4 | 266 | ≤25 | 0.074-0.4 | 88 - 500 | 3300 | 403 |

| Φ5500 x 8500 | 13.8 | 338 | ≤25 | 0.074-0.4 | 108 - 615 | 4500 | 525 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services