Feed size:≤960mm

Motor Power:245-4200KW

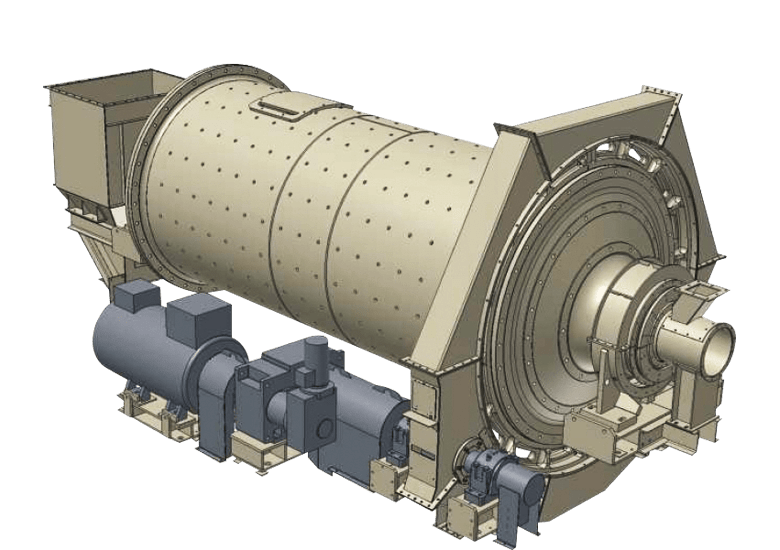

Cement mill (raw material mill) is the key equipment for cement production. It is mainly used in the production industries of building materials, refractory materials, glass ceramics, and salt products to grind cement clinker and other grindable materials. It can be used for Open-flow grinding is also suitable for circular flow grinding combined with powder classifier. It has the characteristics of high grinding efficiency, continuous production, low power consumption, easy adjustment of product fineness and strong applicability to materials. Cement grinding It can be produced by dry method or wet method, and it can also be grinded and dried at the same time.

100% product on-site real shooting, so you can rest assured of your choice!

The cement mill has strong applicability to materials. It can be produced by dry method or wet method, and it can also be grinded and dried at the same time.

The structure of the mill adopts the advanced internal powder selection special compartment device, the fine grinding compartment is equipped with an activation device, and the grinding tail has a special discharge grate plate, which minimizes the size of the grinding medium in the grinding compartment and greatly improves the grinding efficiency. To achieve the purpose of high output and low energy consumption.

When grinding slag cement, the output of the cement mill can be increased by 15-20% compared with ordinary mills, and the power consumption can be reduced by about 10%. In addition, the temperature of the finished product can be reduced by 20-40°C, and the fineness of the product can be easily adjusted.

The lubricating method of cement mill adopts oil spoon, oil ring, and automatic oil station to supply oil for lubrication. The three forms can ensure good lubrication of cement mill; the bearing is equipped with cooling water channel to cool with water to ensure the cement mill bearing has a good work condition.

水泥磨为卧式筒形旋转装置,外沿齿轮传动,两仓,格子型球磨机,物料由进料装置经入料中空轴螺旋均匀地进入磨机料仓,该仓内有阶梯衬板或波纹衬板,内装不同规格钢球,筒体转动产生离心力将钢球带到一定高度后落下,对物料产生重击和研磨作用。物料在料仓达到粗磨后,经单层隔仓板进入料仓,该仓内镶有平衬板,内有钢球,将物料进一步研磨,粉状物通过卸料箅板排出,完成粉磨作业。

| Product Specifications | Mill Form | Transmission form | Reducer | Motor power (kw) | Production capacity (t/d) | Total weight (t) | |

| Model | Speed ratio | ||||||

| Φ1.83×7 | Open flow | Edge | ZD60 | 4.5 | 245 | 6.5-8 | 43.8 |

| Φ2.2×7.5 | Open flow | Edge | ZD70 | 5 | 380 | 8-10 | 64.8 |

| Φ2.2×11 | Open flow | Edge | D110 | 35.5 | 630 | 12-13 | 104.6 |

| Φ2.2×13 | Open flow | Edge | D110 | 35.5 | 630 | 16-18 | 114 |

| Φ2.4×13 | Open flow | Edge | D110 | 35.5 | 800 | 20-23 | 130.6 |

| Φ2.6×13 | Open flow | Edge | MFY100 | 19.5 | 1000 | 28-32 | 158 |

| Φ3×9 | Circle stream | Edge | D125 | 41.2 | 1000 | 28-36.5 | 167 |

| Φ3×11 | Circle stream | Edge | D140 | 42.8 | 1250 | 36-47 | 180 |

| Φ3.2×13 | Open flow | Edge | D140 | 36.5 | 1600 | 45-50 | 225 |

| Φ3.5×13 | Circle stream | Edge | JDX1000 | 5.84 | 2000 | 60-65 | 275 |

| Φ3.8×13 | Open flow | Center | MFY250 | 16.5 | 2500 | 60-62 | 320 |

| Φ4.2×13 | Open flow | Center | JQS3550 | 15.6 | 3530 | 85-87 | 380 |

| Φ4.6×14 | Circle stream | Center | JSI160-C | 14.6 | 4200 | 120-135 | 485 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services