Feed size:≤960mm

Motor Power:15-315KW

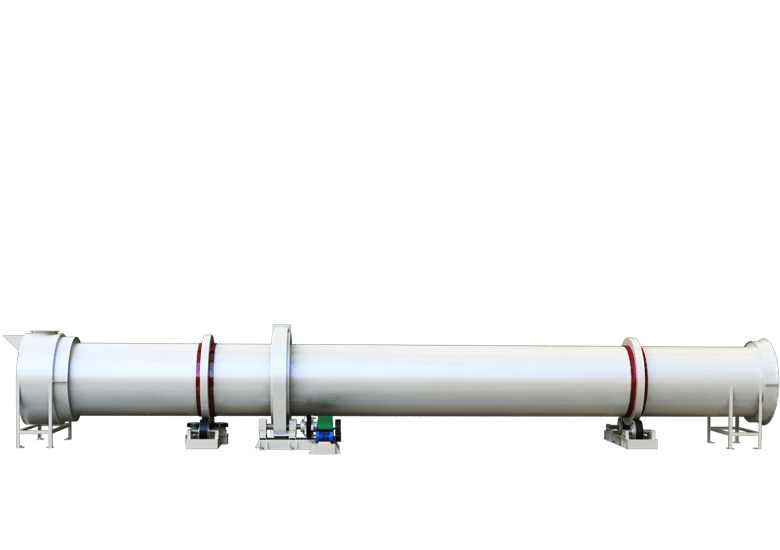

A chiller is a machine that achieves refrigeration through vapor compression or absorption cycles. The function of this equipment is to cool the clinker (1000-1300°C) coming out of the rotary kiln to (below 200°C), and at the same time improve the quality and grindability of the clinker. It is one of the main configuration equipment of the rotary kiln production system. Compact structure, high cooling efficiency, reliable performance and so on. Industrial coolers can be divided into single cylinder coolers, double cylinder coolers, grate coolers, clinker coolers, etc.

100% product on-site real shooting, so you can rest assured of your choice!

The equipment has compact structure, easy operation, convenient maintenance, reliable performance and high operation rate, especially suitable for small cement plants.

The time for cooling the clinker is short, the speed is fast and the efficiency is high, and the temperature of the clinker after cooling is low.

The single cylinder cooler can send all the air after cooling the material into the kiln as secondary circulating air, which improves the thermal efficiency of the rotary kiln.

It is used in the production of compound fertilizers to cool fertilizers with a certain temperature and particle size. When used together with a dryer, it can greatly increase the cooling speed, reduce labor intensity, and increase output. At the same time, it can be used for cooling other powdery and granular materials.

The high-temperature clinker enters the cooler through the feeding device, and the rotation of the cooler drives the material to fully exchange heat with the air. At the same time, as the kiln body rotates continuously according to the designed slope and speed, the material also rolls forward periodically in the kiln. In this way, the raw material is transported from the feed end to the discharge end, and it is ensured that the material is cooled to below 200°C during the time when the material passes through the rotary kiln.

| Product Specifications | Production capacity (t/d) | Installation slope (%) | Main reducer | Main motor (kw) | Total weight (t) |

| Φ1.5×15 | 2-3 | 3-5 | ZQ500 | 15 | 28 |

| Φ1.5×20 | 3-4 | 3-5 | ZQ500 | 15 | 35 |

| Φ1.8×18 | 4-6 | 3-5 | ZQ500 | 18.5 | 47 |

| Φ2.0×22 | 7-8.5 | 3-5 | ZQ500 | 22 | 61 |

| Φ2.2×18 | 7-8.5 | 3-5 | ZQ500 | 22 | 64 |

| Φ2.2×22 | 8-10 | 3-5 | ZQ650 | 30 | 73 |

| Φ2.4×24 | 12-15 | 3-5 | ZS125 | 45 | 98 |

| Φ2.5×25 | 15-20 | 3-5 | ZS125 | 55 | 110 |

| Φ2.8×28 | 16-22 | 3-5 | ZL100 | 55 | 130 |

| Φ3.0×30 | 20-25 | 3-5 | ZL115 | 75 | 169 |

| Φ3.2×36 | 28-32 | 3-5 | ZL115 | 90 | 200 |

| Φ3.3×40 | 32-36 | 3-5 | ZL130 | 132 | 237 |

| Φ3.6×36 | 35-38 | 3-5 | ZSY450-28 | 185 | 318 |

| Φ4.0×36 | 50-60 | 3-5 | ZSY450-25 | 220 | 348 |

| Φ4.0×45 | 60-70 | 3-5 | ZSY450-25 | 250 | 414 |

| Φ4.5×50 | 70-75 | 3-5 | ZSY500-25 | 315 | 576 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services