Feed size:<25mm

Motor Power:95-1250KW

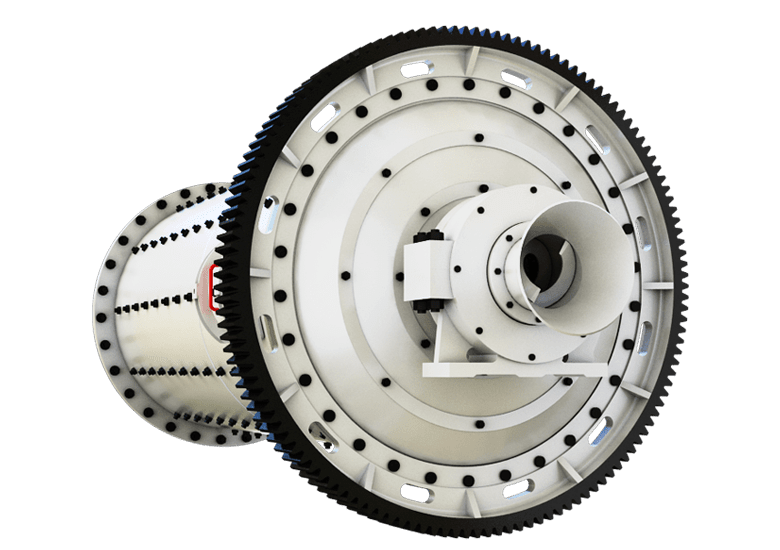

The raw coal enters the feeding device of the air-swept coal mill from the feeding equipment, and the hot air with a temperature of about 300°C also enters the feeding device through the air inlet pipe. The drying bin is equipped with a special lifting plate to raise the raw coal. The raw coal is dried here through intense heat exchange, and the dried coal enters the grinding bin through the double-layer partition board equipped with lifting plates. Grinding body (steel ball) is installed in the grinding chamber, and the coal block is crushed and ground into coal powder in this chamber. While the coal is crushed, the pulverized coal powder and gas will be taken out of the mill through the discharge device of the air-swept coal mill by a special induced draft fan, and the coarser particles will be returned through the return screw of the discharge device. Go to the grinding chamber for re-grinding.

100% product on-site real shooting, so you can rest assured of your choice!

Capable of continuous production, large production capacity, high grinding efficiency, easy adjustment of fineness, and low energy loss.

It has strong adaptability to materials, and can grind and dry coal with various hardness.

The feeding device of this mill adopts a louver-type structure with oblique wind and oblique feeding, which enhances the heat exchange capacity of the coal mill and makes the feeding more smooth, so as to effectively prevent the material blocking phenomenon at the entrance of the coal mill.

The equipment has compact structure, less transmission parts, low maintenance cost, stable operation and convenient installation.

The raw coal enters the feeding device of the air-swept coal mill from the feeding equipment, and the hot air with a temperature of about 300°C also enters the feeding device through the air inlet pipe. The drying bin is equipped with a special lifting plate to raise the raw coal. The raw coal is dried here through intense heat exchange, and the dried coal enters the grinding bin through the double-layer partition board equipped with lifting plates. Grinding body (steel ball) is installed in the grinding chamber, and the coal block is crushed and ground into coal powder in this chamber. While the coal is crushed, the pulverized coal powder and gas will be taken out of the mill through the discharge device of the air-swept coal mill by a special induced draft fan, and the coarser particles will be returned through the return screw of the discharge device. Go to the grinding chamber for re-grinding.

| project specification | Φ1.7×2.5 | Φ2.2×4.4 | Φ2.4×4.75 | Φ2.4×4.5+2 | Φ2.6×5.25+2.25 | Φ2.8×5+3 | Φ3.0×6.5+2.5 | Φ3.2×6.75+2 | Φ3.4×6+3 | Φ3.8×7+2.5 |

| Cylinder speed (r/min) | 24.5 | 22.4 | 20.4 | 20.4 | 19.7 | 18.3 | 18.3 | 16.9 | 17.5 | 16.4 |

| Production capacity (t/h) | 3-5 | 8-9 | 12-14 | 11-12 | 13-14 | 16-17 | 19-20 | 25-30 | 28-30 | 38-40 |

| Feed size (mm) | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 |

| Loading capacity of grinding body (t) | 7.5 | 20 | 22 | 22.5 | 28 | 32 | 43 | 50 | 55 | 80 |

| Main reducer | ZD40 | ZD60 | ZD60 | ZD60 | ZD70 MBY450 |

ZD70 MBY500 |

ZD80 MBY560 |

JDX560 | JDX710 | MBY800 |

| Main motor (kw) | 95 | 250 | 280 | 315 | 400 | 500 | 630 | 710 | 800 | 1250 |

| Total weight (t) | 29 | 46 | 54 | 76 | 98 | 107 | 124 | 148 | 162 | 215 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services