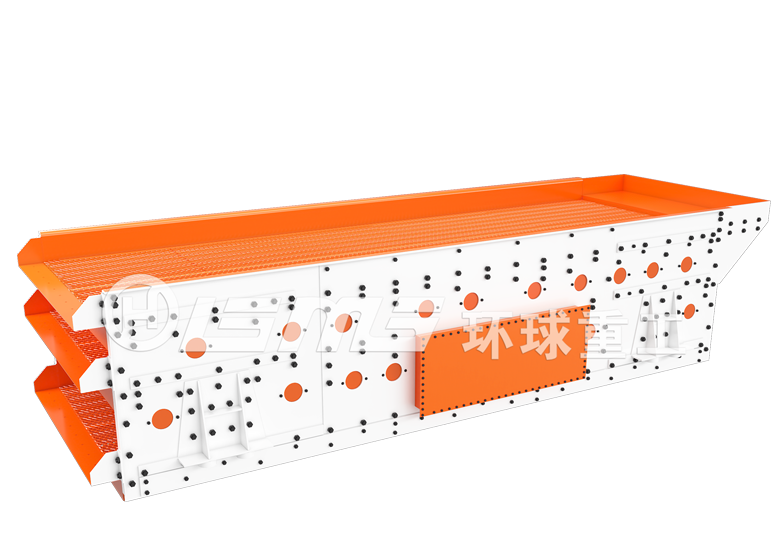

Sieve specification:2400mm*6000mm

Motor Power:30-55KW

The power source of TSK series three-axis horizontal screen consists of six sets of NJ vibrator. The elliptical motion of the screening machine is combined with high vibration intensity to achieve higher efficiency operation than traditional screening machines, showing better performance in terms of processing capacity and screening efficiency, suitable for large, medium and small size material screening .

100% product on-site real shooting, so you can rest assured of your choice!

The elliptical motion of the screening machine is combined with high vibration intensity, so as to achieve higher efficiency operation than traditional screening machines, and show better performance in terms of processing capacity and screening efficiency.

The screen machine adopts an integral beam frame structure in the longitudinal direction, and high-strength torsional shear bolts are used to fasten the side plate and the beam frame; it is equipped with NJ modular vibration exciter, which has greater vibration intensity and longer bearing life.

Amplitude and vibration direction angle can be adjusted to better meet the screening requirements of various materials, without stagnation; easy to adjust; strong applicability, suitable for dry and wet processing of soft, hard and viscous materials craft.

Grease isolation lubrication is used, so that there is no risk of grease contamination and no risk of thin oil leakage; the grease is automatically lubricated every 50 hours (automatic grease injection device is required), and the thin oil lubrication cycle can reach 2000 hours.

Working principle of TSK series triaxial horizontal

Working principle of TSK series triaxial horizontal

TSK series three-axis horizontal screen is a screening equipment with three-axis block eccentric exciter as excitation source, rubber support spring as elastic element, and screen box exciter as movable parts. The three shafts of the vibrator are equipped with counterweights with equal eccentric mass and the same eccentric radius. The power is transmitted from the motor to the driving shaft through the belt, and then transmitted through the gear with a speed ratio of 1, so that the three shafts rotate at the same speed, thereby generating an exciting force, and making the screen box perform forced continuous elliptical motion. The material is driven by this movement, and continuously throws along the circular direction on the horizontal screen surface, and moves forward while throwing up loose layers, and completes the process of particle size classification and forward conveying repeatedly.

| Model | Sieve surface width (mm) | Sieve surface length (mm) | Inclination (°) | Number of vibrations (min) | Double amplitude (mm) | Power (kw) | Weight (kg) |

| 2TSK1648 | 1600 | 4800 | 5(0-10) | 700-850 | 8.0-16.0 | 30 | 7640 |

| 3TSK1648 | 1600 | 4800 | 5(0-10) | 700-850 | 8.0-16.0 | 30 | 9500 |

| 2TSK1860 | 1800 | 6000 | 5(0-10) | 700-850 | 8.0-16.0 | 37 | 10400 |

| 3TSK1860 | 1800 | 6000 | 5(0-10) | 700-850 | 8.0-16.0 | 37 | 12590 |

| 2TSK2460 | 2400 | 6000 | 5(0-10) | 700-850 | 8.0-16.0 | 45 | 16500 |

| 3TSK2460 | 2400 | 6000 | 5(0-10) | 700-850 | 8.0-16.0 | 55 | 18600 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services