Feed size:≤150mm

Motor Power:5.5-37KW

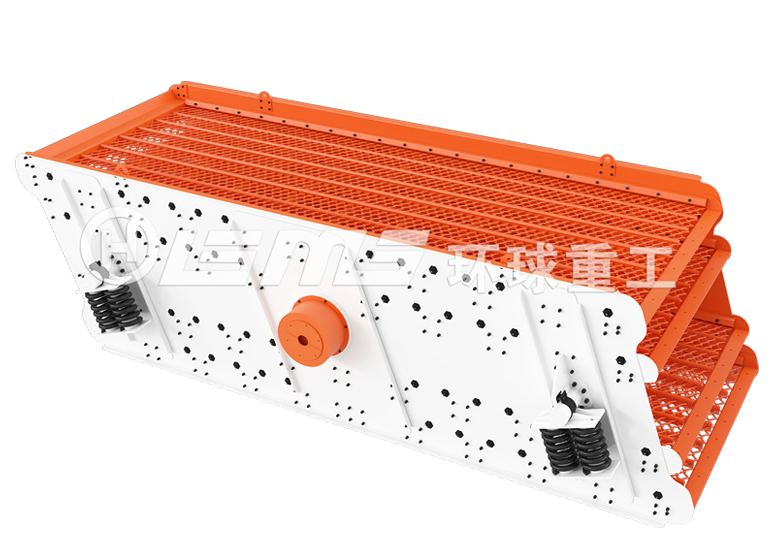

Circular vibrating screen is a multi-layer, new type of vibrating screen, also known as grading screen or screening machine, etc. It is a kind of common screening equipment. YZK series circular vibrating screen is mainly composed of screen box, screen mesh, vibrator and damping spring. High, widely used in product classification in mining, energy, chemical, transportation, building materials, sand making and other industries.

100% product on-site real shooting, so you can rest assured of your choice!

The excitation force can be adjusted, the flow rate can be changed and controlled at any time, and the adjustment is convenient and stable; multi-layer screening, each specification is clearly screened, and the screening efficiency is high.

The structure adopts cylinder type exciter and partial block adjustment device. The advanced rivet connection assembled frame structure improves the service life of the equipment, and the spring damping device reduces the impact on the foundation. In normal use, work Less chance of sudden failure in

The parts that directly contact the material are all made of stainless steel, which is easy to clean, the screen design is exquisite and durable, the efficiency is high, the mesh is not blocked, and there is no flying powder

Using rubber vibration isolation spring, it has long service life, low noise and stable over-resonance area. The fuselage adopts a closed structure, which can effectively prevent dust pollution.

When the YZK series circular vibrating screen is working, the motor drives the eccentric block of the exciter to rotate at high speed through the triangle belt. The running eccentric block produces a large centrifugal force, which excites the screen box to produce a circular motion with a certain amplitude. The material on the screen receives the impulse transmitted by the screen box on the inclined screen surface and produces continuous throwing motion. The process of the material meeting the screen surface In the middle, the particles smaller than the sieve are sieved to achieve classification.

| Model | Screen surface specification W×L(mm) | Number of sieve layers | Feed size (mm) | Sieve hole size (mm) | Production capacity (t/h) | Power (kw) | Vibration frequency (r/min) | Double amplitude (mm) |

| 2YZK1237 | 3700×1200 | 2 | ≤400 | 3-50 | 30-100 | 5.5 | 970 | 5-9 |

| 3YZK1237 | 3700×1200 | 3 | ≤400 | 3-50 | 30-100 | 7.5 | 970 | 5-9 |

| 2YZK1548 | 4800×1500 | 2 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 3YZK1548 | 4800×1500 | 3 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

| 2YZK1848 | 4800×1800 | 2 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 3YZK1848 | 4800×1800 | 3 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

| 4YZK1848 | 4800×1800 | 4 | ≤400 | 3-80 | 56-330 | 22 | 970 | 5-9 |

| 2YZK1860 | 6000×1800 | 2 | ≤400 | 3-100 | 65-586 | 18.5 | 970 | 5-9 |

| 3YZK1860 | 6000×1800 | 3 | ≤400 | 3-100 | 65-586 | 22 | 970 | 5-9 |

| 4YZK1860 | 6000×1800 | 4 | ≤400 | 3-100 | 65-586 | 30 | 980 | 5-9 |

| 2YZK2160 | 6000×2100 | 2 | ≤400 | 3-100 | 81-720 | 22 | 980 | 5-9 |

| 3YZK2160 | 6000×2100 | 3 | ≤400 | 3-100 | 81-720 | 30 | 970 | 5-9 |

| 4YZK2160 | 6000×2100 | 4 | ≤400 | 3-100 | 81-720 | 30 | 980 | 5-9 |

| 2YZK2460 | 6000×2400 | 2 | ≤400 | 3-150 | 100-810 | 22 | 970 | 5-9 |

| 3YZK2460 | 6000×2400 | 3 | ≤400 | 3-150 | 100-810 | 30 | 980 | 5-9 |

| 4YZK2460 | 6000×2400 | 4 | ≤400 | 3-150 | 150-850 | 37 | 980 | 5-9 |

| 2YZK2870 | 7000X2800 | 2 | ≤400 | 5-100 | 120-680 | 22x2 | 750 | 8 |

| 3YZK2870 | 7000X2800 | 3 | ≤400 | 5-100 | 180-720 | 22x2 | 750 | 8 |

| 2YZK3070 | 7000X3000 | 2 | ≤400 | 5-100 | 200-700 | 37 | 750 | 8 |

| 3YZK3070 | 7000X3000 | 3 | ≤400 | 5-100 | 230-800 | 45 | 750 | 8 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services