Feed size:≤1000mm

Motor Power:1.1x2-37KW

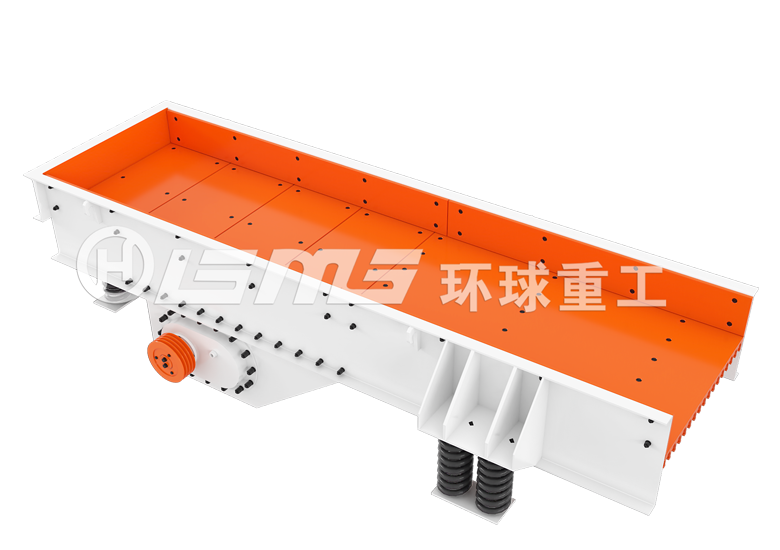

Vibrating feeder, also known as vibrating feeder, is used in the production process to uniformly, regularly and continuously feed blocky, granular and powdery materials from the storage warehouse or hopper to the receiving device. kind of equipment. The equipment is divided into steel plate structure and grate structure. The feeder with steel plate structure is mostly used in the sand and gravel production line, and the material is evenly sent to the crushing equipment; It is more economical and reasonable in preparation. The vibrating feeder adopts the structural characteristics of double eccentric shaft exciters. The equipment can successfully withstand the impact of falling bulk materials and has a large feeding capacity. It is widely used in metallurgy, coal mines, mineral processing, building materials, chemicals, abrasives and other industries. , The essential equipment in the joint operation of screening.

100% product on-site real shooting, so you can rest assured of your choice!

Using double eccentric shafts as the excitation source, the amplitude is stable, ensuring the fluidity of the vibrated ore material and avoiding material flushing

Special grate design , can effectively prevent channel blockage, and play a primary screening of materials, thereby improving production efficiency. The spring device buffers the vibration of the body, effectively avoiding damage to the body and prolonging the service life.

The equipment is small in size, light in weight and simple in structure. No rotating parts, less wearing parts, easy maintenance.

Adapt to various minerals, especially viscous ore materials Strong resistance, and can work in dusty or watery environment.

The vibrating feeder is composed of a feeding trough, a vibrator, a grate bar, a spring support, a transmission motor part, and a V-belt. The vibrating feeder uses the rotation of the eccentric block in the vibrator to generate centrifugal force, so that the movable parts such as the screen box and the vibrator perform forced continuous circular or approximate circular motion. The vibration source of the trough vibratory feeding is the exciter, which is composed of two eccentric shafts (active and passive) and a gear pair. The motor drives the active shaft through the V-belt, and then the gear on the active shaft meshes with the passive shaft. When rotating, the active and passive shafts rotate in opposite directions at the same time, which makes the tank body vibrate, so that the material flows continuously and achieves the purpose of conveying materials.

| Model | Material tank size (mm) | Feed size (mm) | Motor power (kw) | Production capacity (t/h) | Dimensions (mm) |

| GZD-650X2300 | 650X2300 | ≤300 | 1.1X2 | 80 | 2300X1360X780 |

| ZSW-850X3000 | 850X3000 | ≤400 | 7.5X11 | 80-120 | 3110X1800X1600 |

| ZSW-960X3800 | 960X3800 | ≤500 | 11-15 | 120-210 | 3850X1950X1630 |

| ZSW-1100X4200 | 1100X4200 | ≤580 | 18.5 | 200-430 | 4400X2050X1660 |

| ZSW-1100X4900 | 1100X4900 | ≤580 | 18.5 | 280-500 | 5200X2050X1700 |

| ZSW-1300X4900 | 1300X4900 | ≤650 | 22 | 450-600 | 5200X2350X1750 |

| ZSW-1300x6000 | 1300x6000 | ≤700 | 30 | 450-680 | 6100X2350X1750 |

| ZSW-1500X6000 | 1500X6000 | ≤1000 | 37 | 400-800 | 6100X2550X1860 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services