Feed size:≤10mm

Motor Power:reference form

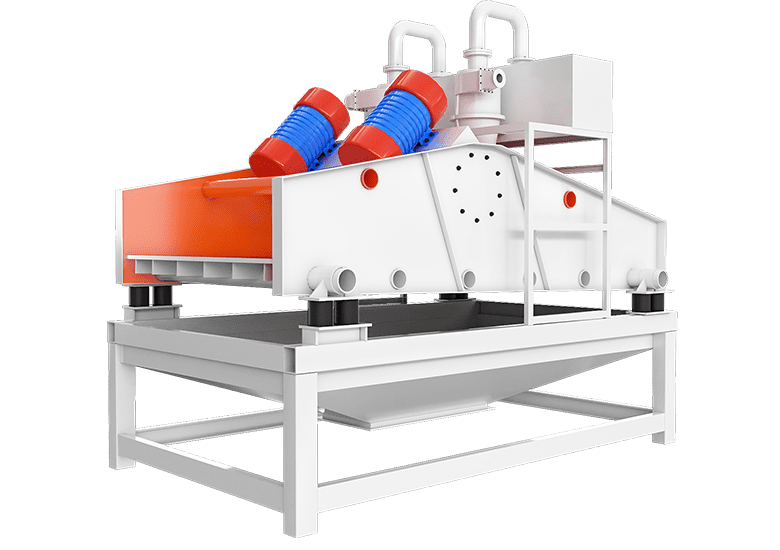

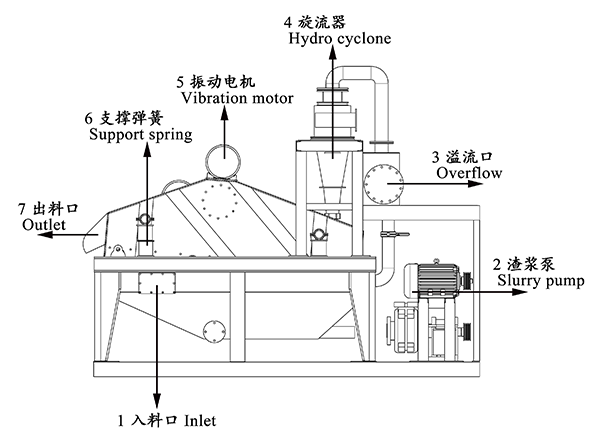

Fine sand recovery machine Our company absorbs foreign advanced technology and designs an advanced fine material extraction device in combination with the actual situation of sand powder. The main feature of this machine is that it can well solve the problem of fine sand loss in the sand making industry. The fine sand recovery machine uses the slurry pump to inject the slurry with a concentration of ≤40% into the hydrocyclone separator for separation, and the separated coarse particles enter the dewatering screen for dehydration and recovery, and the material above 75mm is recovered to the maximum extent, and the material of 75mm or more is removed. The following sludge and clay can reduce the loss of fine sand and the environmental pollution caused by fine sand discharge as much as possible, and improve the utilization rate of resources.

100% product on-site real shooting, so you can rest assured of your choice!

Clean sand washing, high recovery rate, the finished sand can be dehydrated after secondary washing, up to 80% %-90% fine sand recovery effect.

Fine particles are fully recovered, reducing the sedimentation tank The workload reduces the cleaning cost of the sinkhole

It has three functions of cleaning, dehydration and recycling, saving cost and floor space.

The vibrating screen adopts polyurethane screen, which is better than other types Screens last longer without clogging holes.

The main structural components of the BX fine sand recycling machine are composed of: motor, vacuum high-pressure pump, sediment separator, ZKR dewatering screen, cleaning tank, return box, etc. When working, the pump slurry sand-water mixture is transported to the high-pressure mud-sand separator, and the tailings with centrifugally graded concentration are supplied to the dewatering screen through the grit settling nozzle. The material box returns to the cleaning tank again, and when the liquid level in the cleaning tank is too high, it is discharged through the discharge port. The weight concentration of the material recovered by the dewatering screen is 70%-85%. The fineness modulus can be adjusted by changing the pump speed, changing the mortar concentration, adjusting the overflow water volume, and replacing the mortar nozzle. Thereby completing three functions of cleaning, dehydration and grading.

| Model | Separator size (mm) | Dewatering screen material | Dewatering screen power (kw) | Pump motor power (kw) | Vibration motor power (kw) | Sieve surface size (mm) | Production capacity (t/h) |

| BX250 | 250 | High molecular polyurethane | 2x0.55 | 11-17.5 | 2x 0.55 | 700x1800 | 30-80 |

| BX300 | 300 | High molecular polyurethane | 2x0.75 | 11-15 | 2x 0.75 | 900x2000 | 40-100 |

| BX350 | 350 | High molecular polyurethane | 2x0.75 | 15 | 2x 0.75 | 900x2000 | 70-130 |

| BX550 | 550 | High molecular polyurethane | 2x1.1 | 15-22 | 2x 1.1 | 1500x3000 | 100-220 |

| BX650 | 650 | High molecular polyurethane | 2x1.1 | 18.5-30 | 2x 1.1 | 1500x3000 | 120-272 |

| BX750 | 750 | High molecular polyurethane | 2x1.5 | 37-55 | 2x 1.5 | 1500x3000 1800x4000 |

180-350 |

| BX900 | 900 | High molecular polyurethane | 2x2.2 | 55-65 | 2x 2.2 | 1800x4000 2000x5000 |

250-500 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services