Feed size:≤10mm

Motor Power:5.5-2x18.5KW

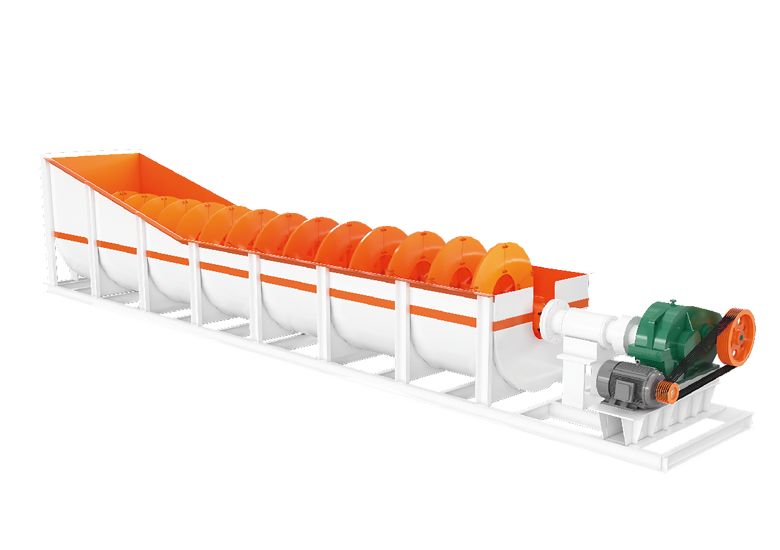

XL spiral sand washing machine, also known as sand washing machine, is divided into single-screw sand washing machine and double-screw sand washing machine. It has the characteristics of reasonable structure, high cleaning degree, large processing capacity and low energy consumption. It can wash away traces of stone powder and impurities from the mixed sand produced by the sand making machine, thereby improving the quality of the sand. The loss of sand during the sand washing process is small, especially its transmission parts are isolated from water and water-receiving materials, and the failure rate is greatly increased. It is lower than the currently commonly used sand washing machine and is very popular among users.

100% product on-site real shooting, so you can rest assured of your choice!

Professional design guide plate and adjustable long overflow weir plate, combined with optimized spiral Speed makes the washing and grading of materials more accurate

The optimally designed discharge groove can ensure the maximum removal of moisture in the material.

This machine has simple structure and stable operation. Suitable for a variety of working environments.

This machine has few wearing parts and low failure rate. long lasting.

When working, the material is evenly fed from the feeding box, and a certain amount of water is continuously injected into the main tank body. The transmission part drives the screw shaft to rotate at a certain speed, forcing the material to turn and roll in the tank body and move to the discharge port. Fine-grained materials and impurities are discharged through the overflow weir along with the overflow water. Coarse-grained materials are discharged from the discharge port, so as to realize the washing, grading, impurity removal and extraction of materials.

| Model | Helix Diameter (mm) | Sink length (mm) | Feed size (mm) | Screw speed (r/min) | Production capacity (t/h) | Power (kw) | Water consumption (t/h) | Dimensions (mm) |

| XL515 | 515 | 7615 | ≤10 | 38 | 5-15 | 5.5 | 6-60 | 8100X2345X1450 |

| XL765 | 765 | 7620 | ≤10 | 26 | 20-60 | 11 | 9-63 | 8545X2650X1870 |

| XL920 | 920 | 7585 | ≤10 | 100 | 40-110 | 11 | 10-80 | 8500X2100X3600 |

| 2XL920 | 920 | 7585 | ≤10 | 200 | 80-220 | 2X11 | 20-160 | 8420X3760X3960 |

| XL1120 | 1120 | 9750 | ≤10 | 175 | 50-130 | 18.5 | 20-150 | 10780X3980X4170 |

| 2XL1120 | 1120 | 9750 | ≤10 | 350 | 100-260 | 2X18.5 | 40-300 | 10970X5250X4720 |

Rooted in China, facing the world. Universal Heavy Machinery always takes "sincere customer service" as the source of company development, subdivides customer needs, and provides tailor-made machinery and equipment.

Free on-site survey to ensure that the scheme design is more in line with customer needs and safer

Strong research and development capabilities provide highly customized equipment for special project requirements

Professional installation, commissioning and maintenance to ensure that the operating characteristics of the equipment meet the needs of production

Professionals come to the site to train operators for you until independent operation

Have a complete accessories system to provide you with reliable and fast accessories services